Revolutionising Waste Management: Producing Green Energy through Waste

Do we ever sit and wonder what happens to the waste generated in our households? Yes, they get picked up by our local waste collectors, but what next? They either end up in landfills or are incinerated. Although municipalities strongly urge people to separate their garbage, it’s likely that the segregated garbage is thrown into a mixed pile with wet and dry waste. As a result, large amounts of trash are left untreated. Out of the 43 million tonnes of the waste collected, only 11.9 Million Tonnes are treated, and the remaining 31 Million Tonnes are dumped in landfill sites. Globally, 2.01 billion tonnes of municipal solid garbage is produced globally each year, with at least 33 percent of that is not treated. The average amount of garbage produced per person per day in the world is 0.74 kilogrammes, but that varies from 0.11 to 4.54 kilos. This highlights the flawed system of waste disposal and management in of our world.

Inefficient waste management systems are an alarming issue. Fortunately, we have a better option. How about we turn these piles of trash into energy?

What is Waste-to-Energy?

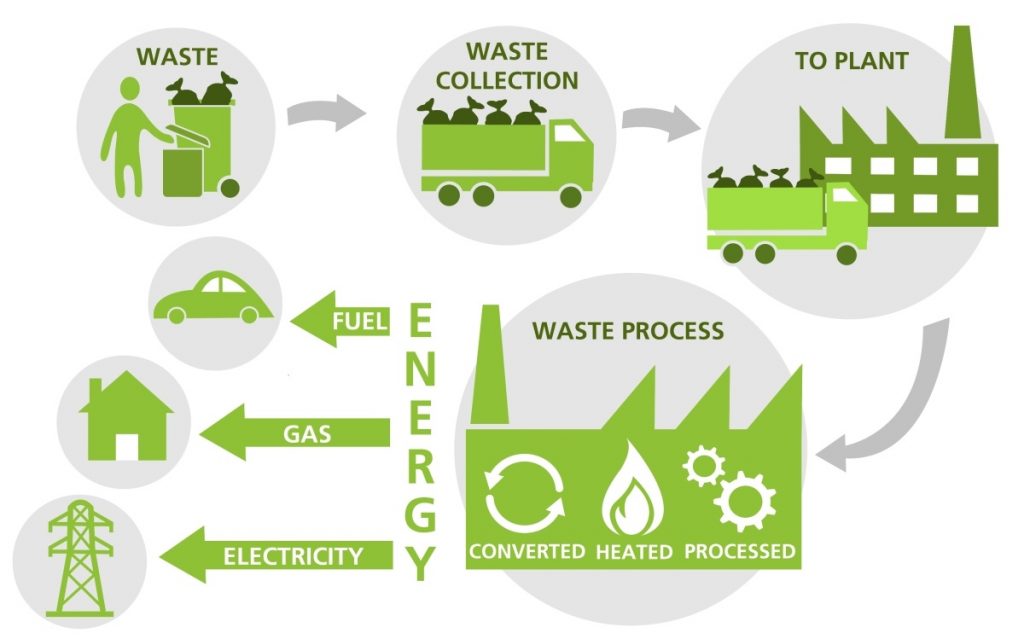

The phrase “waste to energy” (WtE) refers to technologies that turn non-recyclable garbage into usable energy sources like heat, fuels, and electricity. Waste-to-energy or energy-from-waste is a form of energy recovery.

Why green energy from waste?

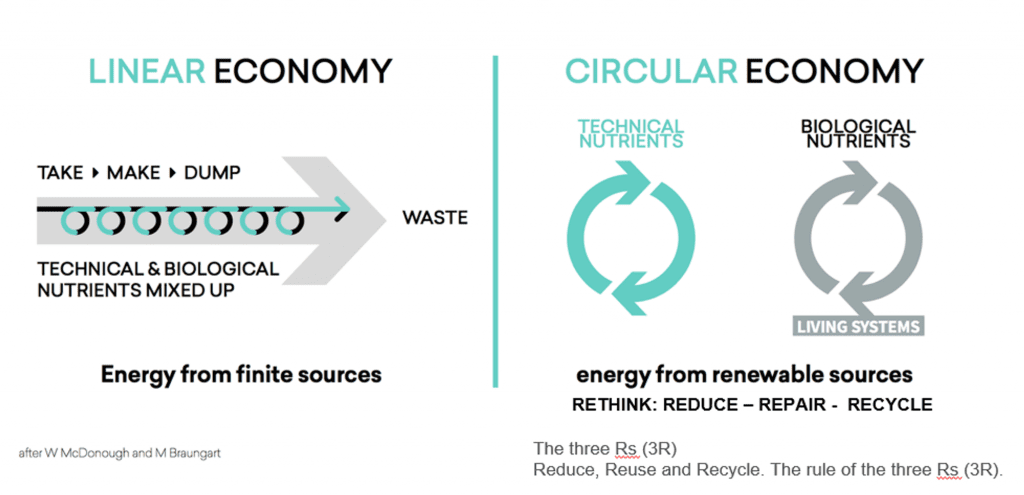

The elements that sustain life on Earth—water, oxygen, nitrogen, and carbon dioxide—flow continuously through cycles of regenerative growth, decay, and rebirth in the biological metabolism. The biological metabolism accrues ‘natural reuse’ rather than creating material liabilities. Waste for one species is food for another. Things grow, then die, and nutrients return to the soil safely. This is nature’s cradle to cradle cycle.

But as people, we’ve chosen a “linear course of action”. We want, we produce, and we discard. We replace our old phones when a new one is released, and we instantaneously toss clothes with the slightest of fades. The journey of our purchase reaching the bins have become significantly shorter. We need easy access to products and carelessly dispose them without a second thought! Each time we do this, we’re eating into a finite supply of resources and often producing toxic waste. Can we alter our perspectives from a linear approach in order to run a circular economy?

How can our waste build capital rather than reduce it?

Waste management is a significant issue in developing nations, and the industry receives incredibly little funding, which has adverse effects on society and the environment.

A more general definition of waste to energy is the process of taking something that one person does not want and turning it into something that the other needs. Changing the way we use energy generally by decarbonizing and distributing. Thus reusing our waste and creating capital through it.

It’s about energy and reevaluating the operating system as a whole. With creativity and invention, we can truly reimagine and create our future, giving us a chance to open new horizons and views rather than staying mired in the difficulties of the present.

Energy Generation through WtE in different countries.

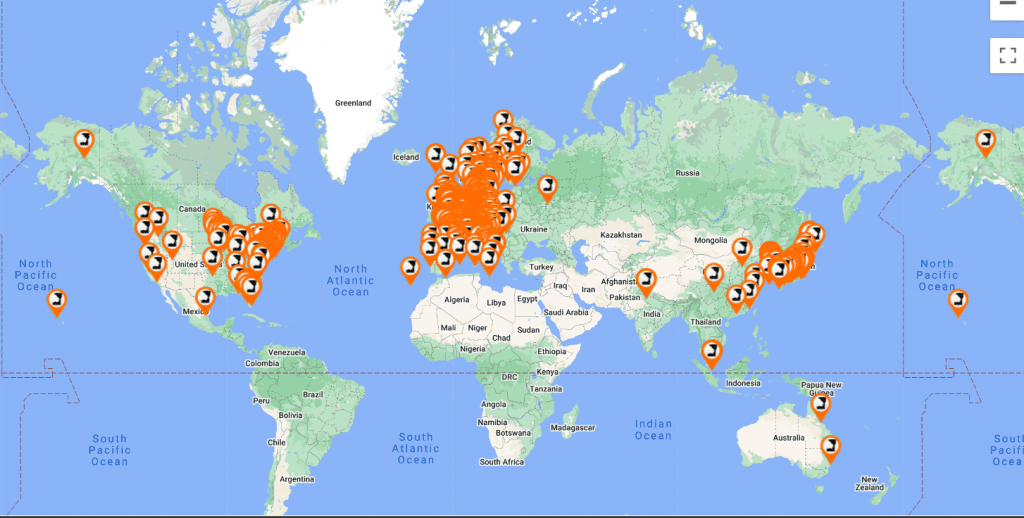

1. US

Waste-to-energy (WTE) has been a tough sell in the U.S. There are currently 75 WTE plants in the U.S., down from 87 roughly ten years ago. Two facilities have closed since 2016. But a new $672 million mass burn facility, the first in the US in more than 15 years, began operating commercially in Palm Beach County, Florida, in 2015. It produces 96 MW of electricity, which is sufficient to run around 40,000 houses and businesses.

2. EUROPE

Waste-to-energy (WTE) is flourishing in Europe. There are 499 WtE Plants operating in Europe (This does not include hazardous waste incineration plants). These plants thermally treat 99 Million tonnes of waste every year. In 2019, the 499 waste-to-energy facilities produced primary energy equal to 13.8 billion m3 of natural gas, which is equivalent to around 9% of the natural gas imported by the EU from Russia. In Europa, Germany, France and UK are the leading countries on energy recovery from MSW resources

3. CHINA

As per the International Energy Agency (IEA), China has around 7.3 gigawatts of installed waste to energy capacity, with its 339 plants during 2017. • China is one of the prominent countries, that has installed the world’s largest incineration plant (The Shenzhen East waste-to-energy plant) in 2019. The plant has a capacity of processing 2.7 million tonnes of waste per year and is capable of generating 1.5 billion kilowatt-hours of power per year.

4. THAILAND

The Thai government has established subsidies and tax incentives for various waste-to-energy plants, including incineration, gasification, fermentation and landfill gas capture. Installed capacity currently stands at 203 megawatts.

Waste to energy data worldwide:

Waste - to Energy (WtE)

Using WtE technologies, non-recyclable waste is transformed into valuable forms of energy. For example, Waste is heated during combustion, creating superheated steam that powers turbogenerators to produce energy.

Given that most towns are running out of landfill sites—the conventional means of disposing of waste—waste management has become essential. Governments must put into place efficient and sustainable waste management strategies, including WTE technologies, due to the steadily declining amount of available land and the burgeoning urban population.

How does a WtE power plant work?

Benefits of Waste-to-energy

1. Reduces the volume of waste

Although WtE systems offer a highly prized source of renewable energy, one of its most important advantages today may be their capacity to turn garbage into ash, which can cut the amount of waste going to landfills by up to 90%.

2. Reduces methane emissions from landfills

Since our waste is getting reused to form of energy, less and less amount of trash reaches landfills. This trash, otherwise, would’ve been dumped in landfills and would’ve produced methane. Hence, WtE methods also help in reducing methane emissions. We talk more about methane emissions from waste in this article.

4. Reduces Land Requirements.

It’s fairly obvious how converting our waste to energy reduces our demand for land (or landfills). The quantity of waste that ends up in landfills can be significantly decreased by redirecting our waste to WtE plants.

Disadvantages of waste to energy:

1. Toxic waste emissions

“Today, the United States burns more than 30 million tons of garbage annually-roughly 13% of its total generated waste. The nation’s initial foray into incineration was a toxicological disaster. One study conducted in the 1980s of a New Jersey incinerator showed the following results: If 2,250 tons of trash were incinerated daily, the annual emission would be 5 tons of lead, 17 tons of mercury, 580 pounds of cadmium, 2,248 tons of nitrous oxide, 853 tons of sulfur dioxide, 777 tons of hydrogen chloride, 87 tons of sulfuric acid, 18 tons of fluorides and 98 tons of particulate matter small enough to lodge permanently in the lungs. The study also showed varying amounts of paper and wood involved in the incineration. Essentially, inert hazardous waste goes into an incinerator and bioavailable hazardous and toxic emissions come out.

2. Lower productivity

3. It is not a renewable form of energy

4. Requires sorting of waste

Different Methods of Converting Waste to Energy

There are different technologies and methods of how waste can be converted into energy.

4. Composting

1. Incineration

Incineration is the most widely used process for converting waste to energy and waste management. The waste organics that are gathered are burnt at high temperatures throughout this operation. This process is called thermal treatment. The thermal treatment produces heat, which is then used to produce energy.

Opposition to Incinerators

While capital-intensive facilities, such as incinerators, have been given priority by lenders and donors to satisfy waste disposal needs, the tide is beginning to reverse. Compared to composting, recycling, and even landfilling, incineration is the most expensive waste treatment technology for the construction, maintenance, and operations. Over the years, investors and banks have found incinerators to be appealing due to their high prices, but development organizations like the World Bank and Germany’s GIZ are becoming more and more aware of the negative effects of incineration, whether or not energy is recovered.

2. Depolymerisation

In this process, long hydrocarbon polymers contained in organic matter are broken down into several products, including crude oil. This process is known as hydrous thermal depolymerisation (HTD), which is controlled by water temperature and pressure.

When accumulated biomass is heated, and under pressure for millions of years in the earth’s crust, thermal depolymerisation (TD) takes place.

This method also uses thermal decomposition but in the presence of water and controlled pressure. This procedure involves heating waste organic compounds to a high temperature in order to produce thermal energy. By using this process, we may produce fossil fuels from waste.

The process sounds amazing since it can solve our ever-increasing scarcity of fossil fuels, but large-scale HTD processes are far from being achieved. The entire process is also very expensive.

3. Gasification

In contrast to incinerators, which burn waste and use the produced heat to produce power, gasification doesn’t entail combustion. In the gasification process, waste is heated in a low-oxygen environment. During the chemical process of waste gasification, the rubbish separates into its individual molecules. Inert slag or char and syngas, a flammable gas, are the two byproducts of this process. Syngas can either be processed into a range of valuable products, such as diesel, hydrogen, and useful chemicals, or they can be used directly for the production of electricity.

Depending on the gasification technique, the residue produced by the gasification of municipal wastes may contain different tars, particulates, halogens, heavy metals, and alkaline compounds. This may cause agglomeration in the gasification vessel, which may cause fluidized beds to become clogged and increase tar formation.

4. Composting

The simplest of procedures for converting waste to energy. The previous methods talked about all the steps that big industrialists and governments can take up. But what about us? The most crucial question that all our articles boil down to: What can we do?

Composting recycles and preserves soil nutrients AND doesn’t capture any energy. Anaerobic digestion (AD), which transforms the sugars and starches from food waste into biogas, can be utilized to harness the energy contained in organic materials. This compost can then be used as fertilizers for our plants at home. We talk more about composting here. If composting is managed at a large scale, the biogas produced can then be used to produce electricity.

But there are many challenges to composting. Learn everything on composting through our article here.

Why are Waste-to-Energy plants not widespread in India?

The dwindling number of WtE plants in India makes sense when you look at the rocky history of the plants in India.

In 1987, the first waste-to-energy facility was built in Timarpur, Delhi. The facility, constructed by a Danish company, was designed to burn 300 tons of municipal solid trash every day in order to produce 3.75 megawatts of power.

The factory lasted about 20 days after being established at a cost of Rs 20 crore. According to Dharmesh Shah, a technical advisor with the non-governmental organization Legal Initiative for Forest and Environment, the reason for its failure was the poor quality of waste that was brought to the plant.

Since then, other waste-to-energy plant failures have been reported in India. Seven of the 14 waste-to-energy facilities that were constructed in the country have since been shut down.

Realizing the limitations and failures of the plants, state governments in India have been shifting their focus on waste segregation and reducing waste.

What is the future of Waste-to-Energy Plants?

The market for waste-to-energy on a global scale was estimated to be worth $35.1 billion in 2019 and is anticipated to increase to $50.1 billion by 2027, rising at a CAGR of 4.6% from 2020 to 2027. Even with advancements in recycling, there is always a large amount of residual garbage accessible for energy production. India generates 277.1 million tonnes of solid garbage year, and by 2030, that number is expected to reach 387,8 million tonnes.

The problem with WtE methods is the high price. WtE adoption rates in emerging nations are low since it costs a lot of money to run WtE facilities and upgrade the infrastructure.

The combustion of untreated mixed garbage(incineration) and landfilling both release carbon into the atmosphere, but they do so in different ways and to varying degrees, making waste-to-energy the lesser of two evils. Energy from garbage solely emits carbon dioxide; however, landfills also release methane (which is 25 times more damaging to the atmosphere). Hence, it is thought to have a less negative overall environmental impact.

Check this link out, if you haven’t already:

How Singapore fixed its waste management problem through a WtE Plant.

Singapore, which is regarded as one of the world’s cleanest nations, faces similar difficulties in managing its waste. The amount of solid waste disposed of in the nation has increased around seven-fold from 1,260 tons per day in 1970 to a peak of 8,559 tons per day in 2016, because of the increasing population and growing economy. In 2019, Singapore produced more than 7.2 million tons of solid trash, of which 2.95 million tons could not be recycled. Every year, 96% of the 930 million kg of plastic garbage that must be dumped is non-recyclable.

There was a significant amount of waste that needed to be handled carefully and disposed of effectively. However, Singapore has, over time, discovered a simple solution to this issue.

The journey of trash brings us to the largest waste incineration plant in Singapore to date, Tuas South Incineration Plant (TSIP). It is one of four such plants that can transform waste into electricity in the country.

On average, the Tuas South Incineration Plant receives 600 trucks every day.

The waste is subsequently gathered and fed into the incinerator by cranes. The furnace has a temperature range of 850 to 1,000 degrees. This reduces the volume of waste by 90%.

From the ash, ferrous and non-ferrous metals are recovered through a magnetic separator. After then, ash will be moved from the ash pit to another location. Prior to being discharged into the atmosphere, pollutants created during incineration are cleaned to guarantee that air is not polluted.

The heat produced from the combustion of waste will then be used to turn water into steam. To power turbine generators, this water will subsequently be transformed into high-temperature, high-pressure steam. This is how electricity is generated through waste. 20% of it is used for internal consumption, while the remaining 80% is exported. In 2019, about 1.08 million tons of waste is collected through TSIP. That’s equivalent to about 3,000 tons of waste daily.

The four waste-to-energy incinerators in Singapore, including Tuas South, provide enough energy to meet around 2 to 3% of the country’s overall electrical needs. A future waste-to-energy facility being constructed by Mitsubishi Heavy Industries and the water treatment business ‘Hyflux’ will have the capacity to burn 3,600 tons of garbage per day while generating enough electricity for self-sufficiency and sending any extra back to the national grid.

Conclusion

WtE is one of several imperatives for sustainable waste management. In addition to minimizing the need for landfills in metropolitan areas, providing renewable energy, and earning income for local governments and municipalities, WtE systems can be an efficient complement to fossil fuel-based power sources. We conclude waste to energy can help us move away from fossil fuels in the near-term but is not part of a clean energy future.

It needs to be seen how the technology advances in this sector for the technology to be lot more productive and cost efficiency.